1

/

of

10

Ripack® Multicover 960 Electric Film Sealer

Ripack® Multicover 960 Electric Film Sealer

Regular price

$9,908.84

Regular price

Sale price

$9,908.84

Unit price

/

per

SKU:349025

The RIPACK® Multicover 960's electric sealing bars allows you to create your own pallet shrouds up to 1440mm wide. This allows you customise your shrouds to suit the height of your pallets.

Its width allows you to create shrouds to suit most common pallet sizes such as: 80cm × 120cm, 100cm × 120cm and 120cm × 120cm.

Available standard with a film holder, the Multicover 960 can be fitted with an optional second spool holder.

Technical Specification:

- Sealing process: Electric by adjustable pulse

- Power supply: 230 V (50/60 Hz) - 24 V - 0.5 KVA

- Cutting process: Knife on mobile cart

- Maximum sealing capacity 4 x 200 µ width 1440 mm

- Maximum admissible spool: Ø 500 mm - width 1500 mm

- Length/width/height: 1970 x 580 x 1430 mm

- Weight: 95 Kg

- Package size (L x W x H): 2150 x 750 x 1450 mm

- Package weight: 160kg

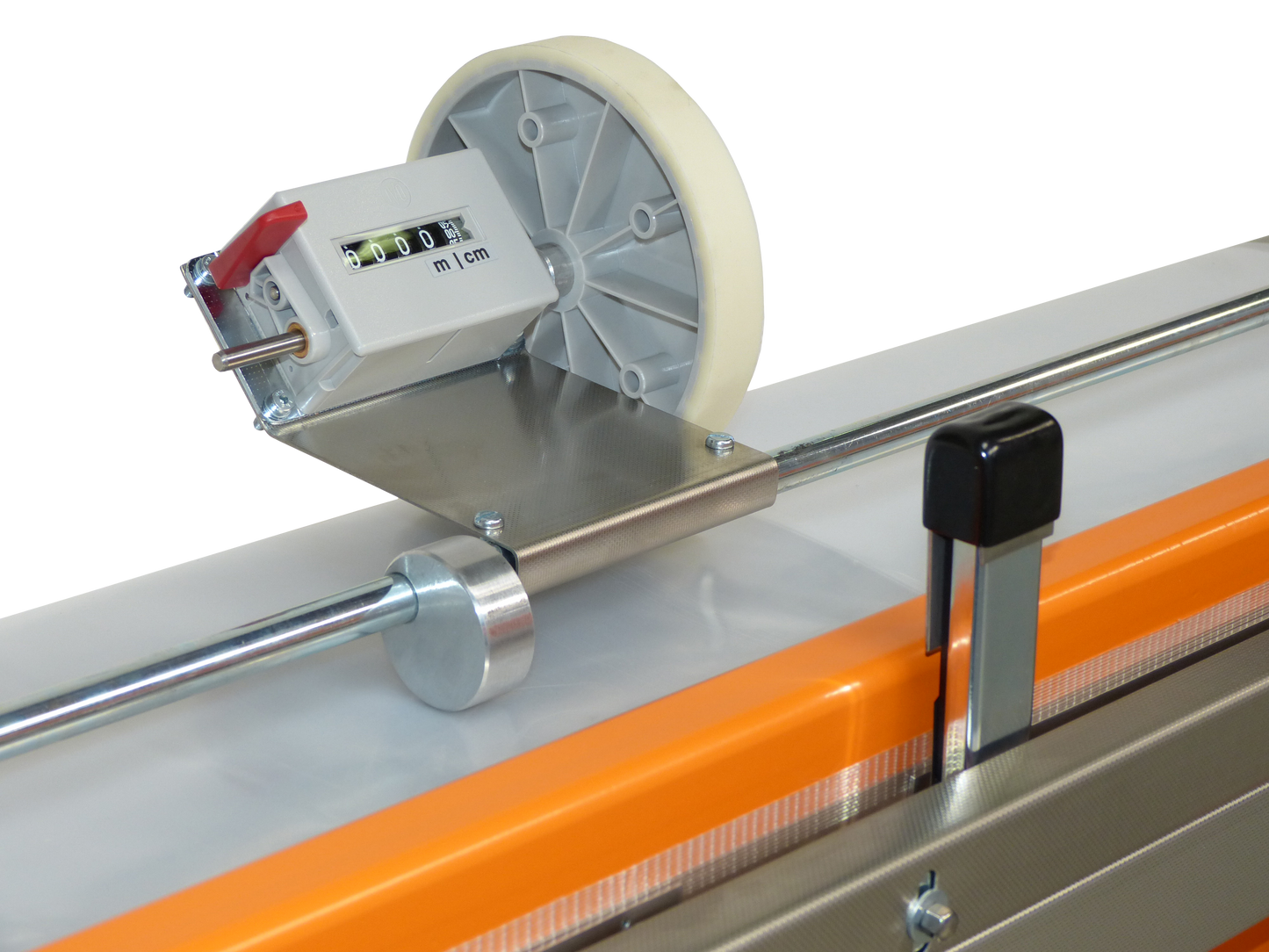

- Built-in counter to keep track of film usage

- 1-year warranty

Couldn't load pickup availability