Ripack® 2500 Fixed Shrinking Station

Ripack® 2500 Fixed Shrinking Station

SKU:RIPACK 2500 F

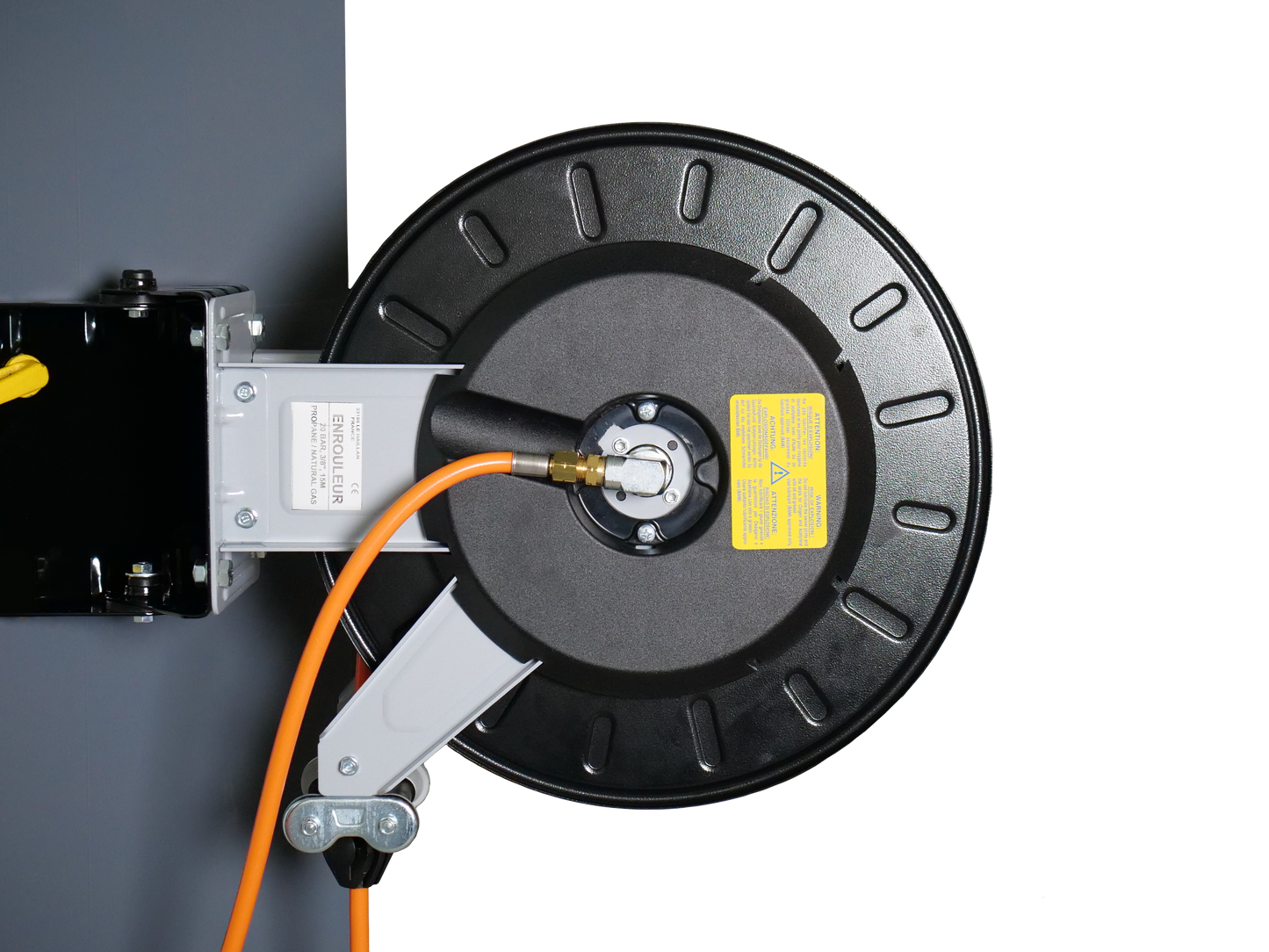

The R2500 F shrinking kit combines the quality of the RIPACK® 2500 heat tool with the ergonomics of the RIPACK® gas hose reel.

This solution is great for a fixed shrink wrapping station where higher production is required.

The combination of the RIPACK® 2500 gun with the 15 meter gas hose reel will guarantee an optimised packing station.

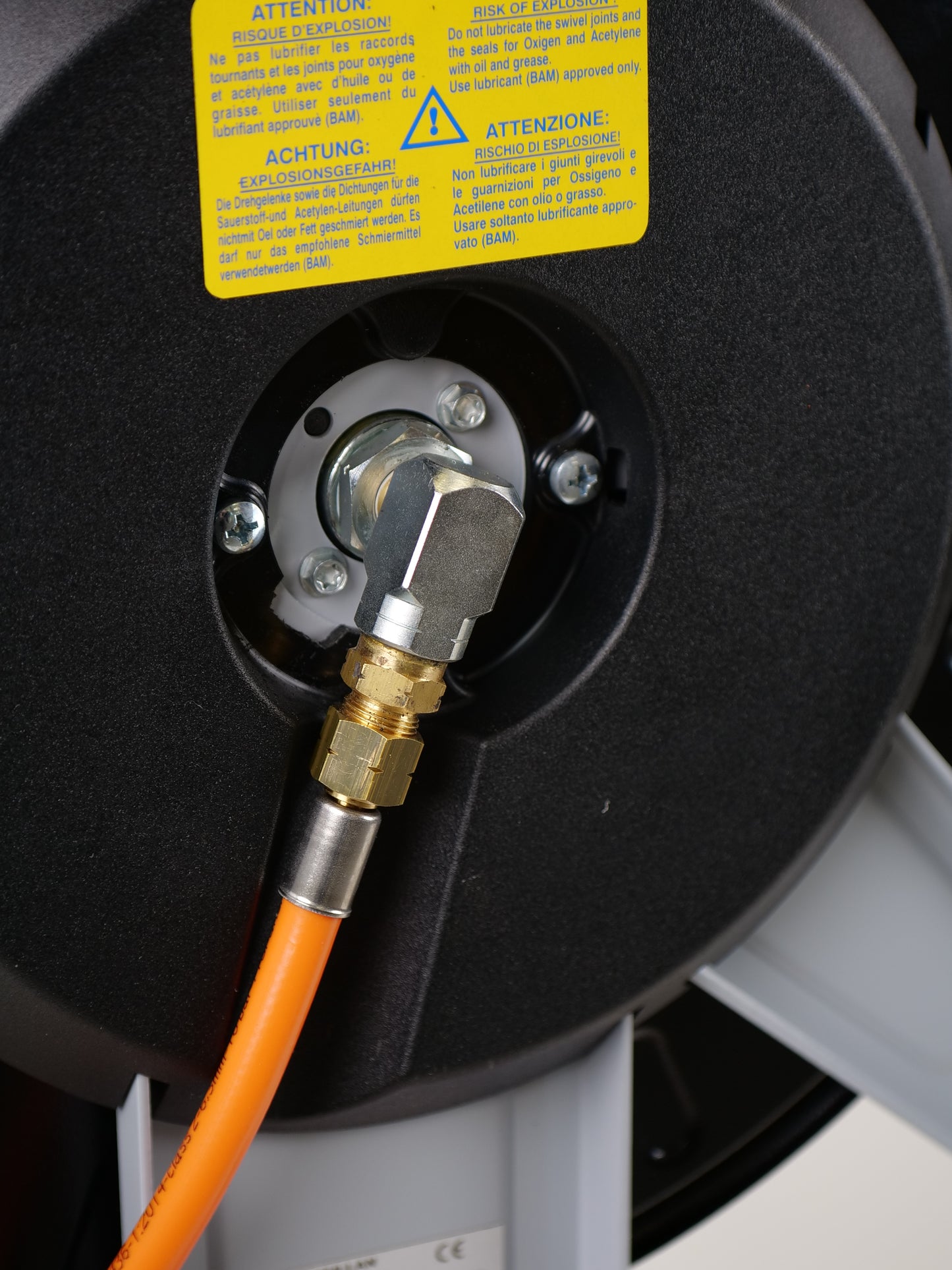

The pivoting arm system on the reel ensures the longevity of your equipment.

The adjustable gas regulator allows the operator to select the appropriate amount of heat required to shrink the material.

Heat Tool:

- Heat output: 34 to 60 kW

- Pressure: 1.5 to 3.5 bars

- Length/height: 360/240 mm

- Weight: 940 g

- Sound level: <85 dbA

- Energy source: LPG

- Package size (L x W x H): 460 x 330 x 140 mm

- Package weight: 4880 g

- Gas consumption: from 2.2 to 4 kg/hour

Hose reel:

- Support: Articulated at 120 °

- Ratchet: Multi-position stop

- Weight: 15.5 kg

- Heat tool connection hose: 15 meter

- Bottle connection hose: 1.5 meter

Couldn't load pickup availability